Increasing microalgae biomass feedstock by valorizing wine gaseous.

Project REDWINE: Increasing microalgae biomass feedstock by valorizing wine gaseous and liquid residues.

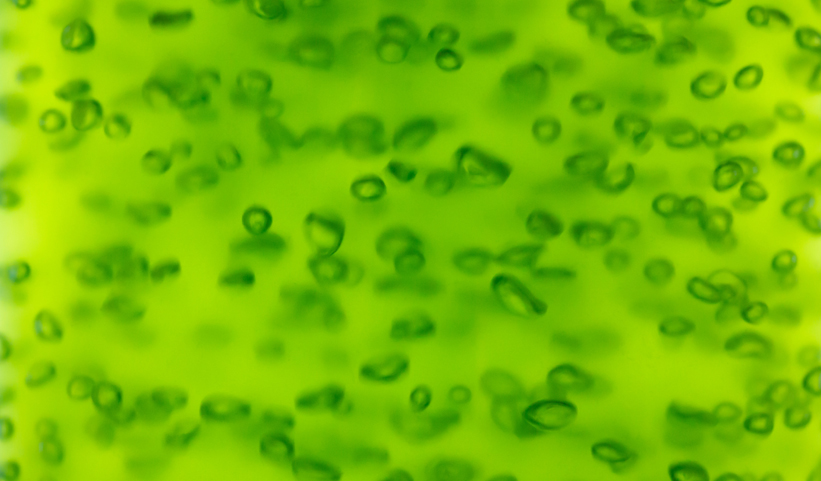

Motivated by an urgent need to mitigate climate change and, particularly, to reduce greenhouse gas emissions from food value chains, REDWINE focuses on the utilization of biogenic carbon dioxide (CO2) from the wine fermentation process for microalgae biomass production and valorization.

A powerful synergy across bio-based industries results in REDWINE’s innovative circular business model, which allows wine manufacturers to efficiently treat their liquid and gaseous effluents while profitably diversifying their revenues through the valorization of Chlorella biomass into multiple high-value ingredients. The REDWINE concept is realized through the establishment of an integrated ‘Living Lab’ demonstrating the technical and economic viability of a system for collection and storage of the offgas and liquid effluents of a 20.000L wine fermenter and its adaptation to microalgae cultivation and energy efficient harvesting technologies, in order to use 90% of the CO2 collected, to produce biomass.

REDWINE aims to demonstrate a circular concept through the development of a simple biorefinery to be deployed in the winery which will yield sustainable and cost competitive ingredients for food formulations (protein and fatty acids), cosmetics (peptides, carotenoid rich oils and active polysaccharides), agriculture (carbohydrates as vine biostimulants) and wine production (proteins for wine clarification). The proposed REDWINE solution is expected to reduce the GHG emissions of the entire wine production value chain by at least 31% while potentially generating over €15M in revenues and creating 45 new jobs for a 7ML size winery on a 3-year time horizon

Our main tasks

- Process modelling for process assessment

- Techno-economic assessment

- Development and evaluation of the multidisciplinary design optimization (MDO) problem problem and the virtual plant of the process

- Logistics: analysis and modelling of the value chain

Partners

AVIPE | LEITAT | INLECOM | LIPOTEC – A LUBRIZOL COMPANY | ALGAMA | PERVATECH | COLDEP | NOVIS | IPS – POLYTECHNIC INSTITUTE OF SETÚBAL | IDENER.AI | LABORATÓRIO NACIONAL DE ENERGIA E GEOLOGIA | A4F – ALGAFUEL

Start date – finish date

05 / 2021 - 04 / 2025

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement Nº 101023567