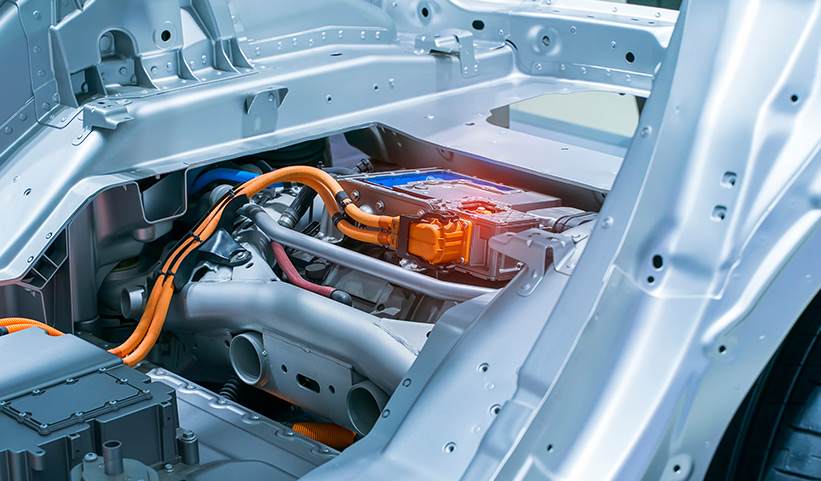

Using AI to optimize the use of recycled materials within the EV revolution.

Project REVOLUTION: Supporting the electric vehicle revolution through maximizing EV range and end-of-life vehicle recovery through optimization of recycled plastics and advanced light materials.

REVOLUTION focusses on overcoming the challenges hindering the use of recycled materials, but more broadly, restricting the widespread adoption of circular economy principles in the automotive industry. Forthcoming end-of-life vehicles directives are expected to recognize the potential for plastics to enable a circular flow of materials in the automotive sector. Implementing minimum post-consumer recycle targets in any new plastic components in vehicles are currently being discussed. These targets have the potential to disrupt the automotive industry.

Currently closed-loop recycling forms ~2% of the total plastics demanded across the automotive sector, and are not used in high-value or high-performing areas. REVOLUTION aims a disruptive innovation to bring open-loop recycling to the forefront of automotive injection moulding. The variability of closed-loop recycling causes a big problem for an industry where failure rates on 1 per million are accepted.

REVOLUTION uses machine learning and artificial intelligence to optimize the input of recycled materials and injection moulding process to deliver high-quality parts. The AI-Platform uses data from three areas of the production process to predict part quality when using recycled materials. REVOLUTION develops this platform along with a range of recycled formulations, including self-reinforced materials to deliver innovative components that offer light weighing, superior performance, and distinctive end of life advantages for future electric vehicles. To that end, REVOLUTION brings together leading organizations from European strong-hold industries such as automotive, chemicals and plastics.

Our main tasks

- Parameter Monitoring and Data Collection

- Development of process model

- Development of Control based on Predictive Model

- Integration of optimised system into shop floor

- Modelling for Advanced Materials

- Process Modelling for Component Manufacture

- Life cycle assessment

- Societal Impact Analysis

- Network Patent Analysis

- Techno-Economic Assessment

- Exploitation of results

- Communication materials and activities

- Stakeholder Engagement and Networking Activities

- Clustering Activities

Partners

CENTRO RICERCHE FIAT | CLARIANT | FARPLAS | FRAUNHOFER | HEATHLAND | ICONIQ | IDENER.AI | IMEC | LYONDELLBASELL | MAIER | NORMER | TOFAS | TRINSEO | VTT

Start date – finish date

01 / 2021 - 12 / 2023

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement Nº 101006631