Breakthrough digital technologies for increased energy efficiency in high-temperature heating processes

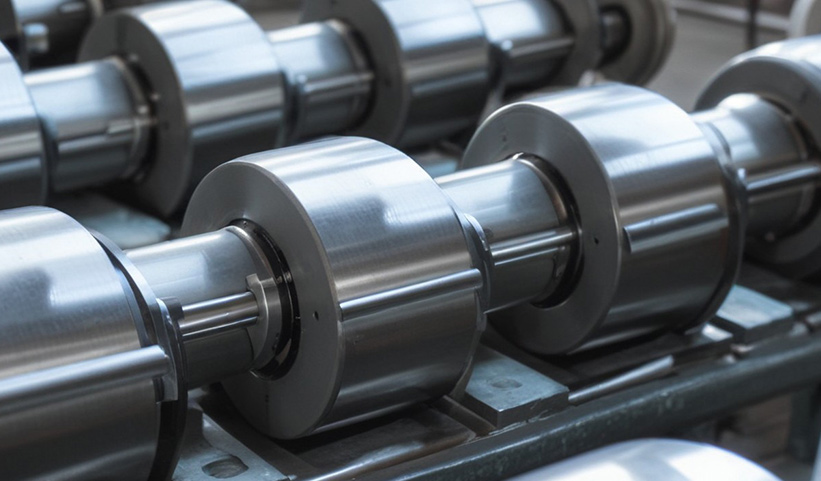

METAWAVE: High-temperature heating processes with breakthrough microwave and digital technologies for increased energy efficiency

METAWAVE introduces advanced microwave-based heating systems in high-temperature heating processes. Its key outcome is the demonstration of these systems in three industrial sectors (ceramics, asphalt, aluminium) achieving superior performance.

Process efficiency, energy use, GHG emissions and productivity are the main metrics that define the positioning of the project results on the industrial innovation atlas. The advantages of higher system efficiency, shorter process time and process controllability have the potential of bringing the twin-transition one step closer, helping the process industries to reduce the energy demand and leverage their overall flexibility. Further optimisation requires feedstock enhancement with novel nanostructured additives, waste-based refractories for advanced process monitoring and controls as well as robust modelling and predictive functions for the Process Digital Twin.

METAWAVE targets seamless integration of renewable energy sources to power the microwave-based heating systems through Virtual Power Plant (VPP) configurations, accompanied by an energy management system based on data-driven modelling optimisation and alongside the investigation of industrial symbiosis developing a detailed Hub 4 Circularity (H4C) roadmap. A complete assessment of the technoeconomic feasibility of the novel technologies and their environmental impact are conducted paving the way towards their up-scale and commercial adoption.

METAWAVE mobilises different stakeholders into new ways of operating process industries through capacity building, open science, and new forms of sustainable economic activity with an emphasis on sustainable fuels and feedstocks. The consortium work together to achieve 420 GWh energy reduction, over 95kt CO2 averted and more than 19% productivity increase yielding total revenues of more than 230M€ and the creation of more than 900 new jobs by 2032.

Our main tasks

- Specification of industrial process requirements.

- VPP design and energy asset digitization.

- Energy management system.

- DSS and user interface.

- Testing and validation.

- Demo and energy efficiency assessment.

Partners

AIMEN | AVANZARE MATERIALS | COPHA | CORE INNOVATION CENTRE | CRIT RESEARCH | EUROCORE CONSULTING | FRICKE UND MALLAH MICROWAVE TECHNOLOGY | GRES ARAGON | IDENER.AI | IMEC R&D | INSTITUTO TECNOLOGICO DE ARAGON | IRES | KMOP POLICY CENTER | MYTILINEOS | NXTCONTROL | SYXIS | TAMPERE UNIVERSITY | UNIVERSITA DEGLI STUDI DI MODENA E REGGIO EMILIAStart date – finish date

01 / 2024 - 12 / 2027

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement Nº 101138476